When it comes to metalworking, precision is everything. Whether you’re building furniture, crafting structural frames, or working on custom projects, a tenon cutter drill for metal is one of the most versatile tools you can own.

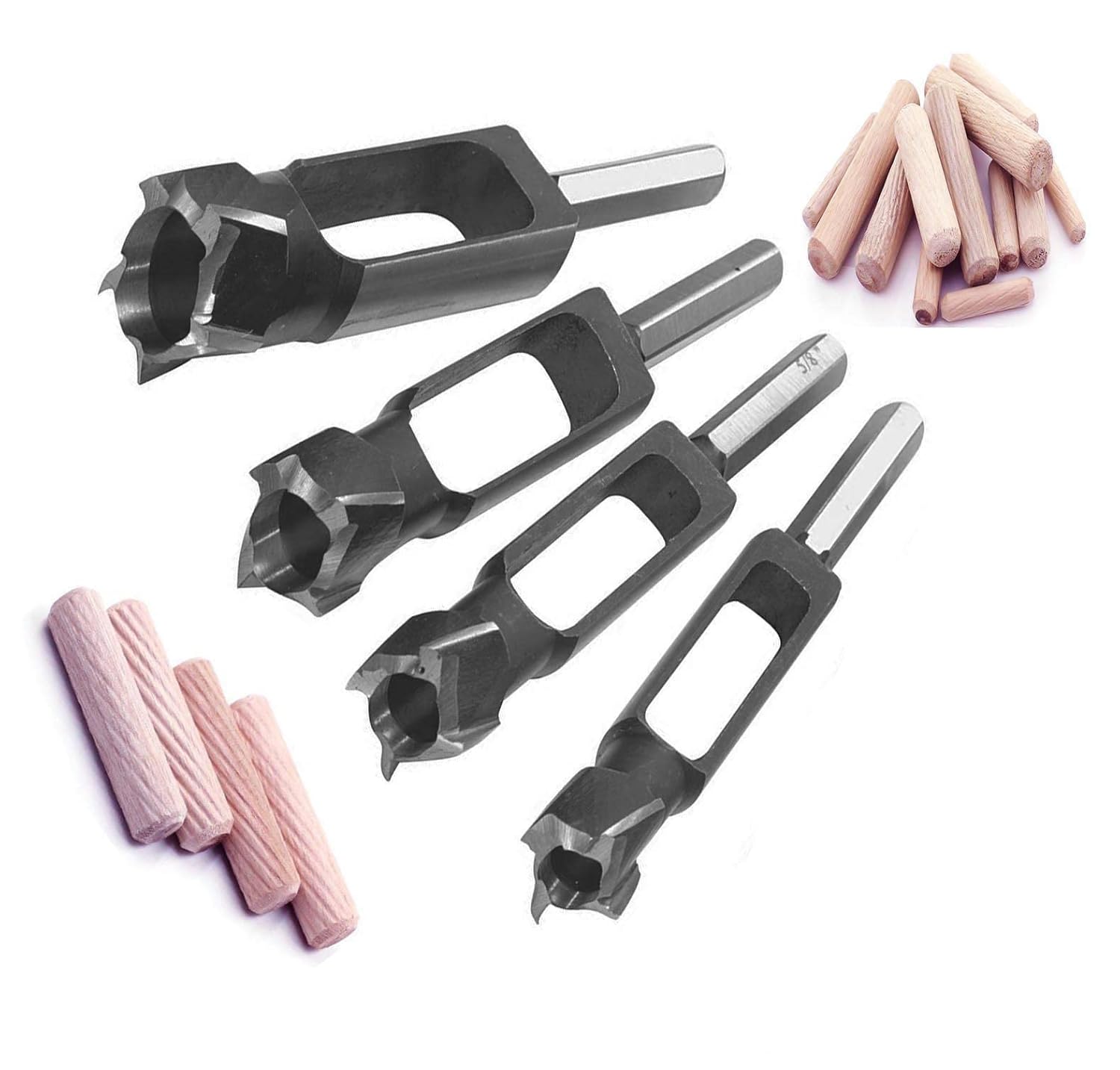

Unlike standard drill bits, tenon cutters allow you to create smooth, rounded tenons and dowels that fit securely into joints—ideal for furniture makers, welders, and DIY metalworkers alike.

However, with numerous cutter sets available on the market, how do you select the right one for your specific needs? This guide explores whether you can use a tenon cutter on a drill press, highlights the key factors to consider before buying, and reviews the best tenon cutter drill for metal available today.

Top Product Reviews & Comparisons

Here are the best tenon cutter drill for metal, carefully reviewed for performance, durability, and value.

Can a Tenon Cutter Be Used on a Drill Press?

Yes, a tenon cutter can be used on a drill press, but with some caveats. Drill presses offer stability and precision, which is beneficial when shaping tenons consistently. However, most tenon cutters are designed for handheld drills or specialized boring machines, meaning you’ll need to:

- Ensure the cutter’s shank is compatible with the drill press chuck.

- Use the proper RPM settings (too fast can overheat the cutter, too slow can cause rough cuts).

- Secure your workpiece tightly, since metal requires steady pressure to avoid chatter or uneven cutting.

For heavy-duty work, especially on steel or hardened alloys, a hand drill with variable speed or a metal-capable boring machine may give you better results. That said, a drill press is still a safe and reliable choice for most DIY and light professional applications.

Key Factors to Consider When Buying the Best Tenon Cutter Drill for Metal

Choosing the right tenon cutter drill for metal is more than just finding a tool that fits your budget. A tenon cutter directly impacts the precision, durability, and overall quality of your work, especially when dealing with tougher materials like steel or aluminum. Below are the most important factors to weigh before making a purchase.

Cutter Size Range

One of the first things to check is the range of diameters a tenon cutter can handle. If you’re only working on small projects, a single-size cutter may be sufficient. However, most professionals and DIYers benefit from sets that include multiple cutter sizes.

- Versatility: A wider size range allows you to switch between thin rods, medium dowels, and thicker joints without buying separate tools.

- Efficiency: Multi-size sets (like 5-piece kits) are particularly useful in workshops where different project types are common.

For example, a hobbyist building small furniture pieces may only need smaller diameters, while a metal fabricator creating structural frames might require larger tenons. Buying a set ensures you’re covered for all scenarios.

Material & Durability

The construction material of the cutter greatly affects its lifespan and cutting performance. Since metal is harder to shape than wood, your tool must be tough enough to handle repeated use without dulling quickly.

Blade Material

- High-carbon steel (HCS): Stronger and longer-lasting than regular steel, making it ideal for mild metals.

- Hardened alloy or HSS (high-speed steel): Best for tougher materials like stainless steel because they resist heat buildup and stay sharper longer.

- Carbide-tipped blades: Premium choice for professionals, offering exceptional durability and cleaner cuts.

Body Construction

- Aluminum: Lightweight and portable, great for occasional or mobile use.

- Steel: Heavier but provides more stability and strength, suitable for industrial or daily applications.

Durability is key—investing in quality materials upfront will save money and frustration in the long run.

Compatibility

Not all tenon cutters work with every drill, so it’s important to check compatibility.

- Handheld Drills: Convenient for mobile projects, but require sufficient torque to handle metal cutting without stalling.

- Drill Presses: Offer more precision and stability, especially for repetitive or large projects.

- Magnetic Drill Presses: Ideal for professional metalworkers, especially when working with heavy or thick materials.

Always verify the cutter’s shank size and the recommended RPM range. Using a drill that’s too fast can overheat the cutter, while underpowered drills may struggle to produce clean cuts.

Precision & Adjustability

When cutting metal, accuracy is everything. Poorly cut tenons not only weaken joints but also increase post-processing work.

- Adjustable Depth: Some cutters allow you to control how deep the tenon goes, offering more customization.

- Replaceable Blades: Instead of replacing the entire cutter, you can swap out worn blades, saving money over time.

- Smooth Cutting Action: High-quality cutters are engineered to minimize chatter and vibration, which reduces the need for extra grinding or sanding afterward.

If precision is a priority in your work—such as in furniture making or professional fabrication—look for cutters with micro-adjustability features.

Portability & Storage

A small but practical factor is how easy it is to carry and store your cutters.

- Carrying Cases: Many high-quality sets come with protective cases, keeping cutters organized and preventing blade damage.

- Compact Design: Lightweight and portable cutters are ideal for contractors or mobile professionals who work at multiple job sites.

Good storage not only prolongs tool life but also saves time by keeping all your cutter sizes in one place.

Price vs. Value

Finally, consider your budget relative to how often and how intensively you’ll use the tool.

- Budget Models: Affordable and effective for hobbyists, occasional repairs, or light DIY projects.

- Mid-Range Sets: Offer better durability and more versatility, ideal for regular workshop use.

- Premium Options: Built with carbide tips or hardened alloys, designed for professionals who need long-lasting tools that can withstand heavy-duty use.

The key is to balance cost with expected performance. For occasional light work, a budget-friendly kit may be enough. But if you’re cutting stainless steel daily, investing in a premium cutter will pay off in reduced downtime and cleaner results.

Final Thoughts

The best tenon cutter drill for metal should combine the right size range, material strength, compatibility, and precision features to suit your needs. Whether you’re a weekend hobbyist or a professional metalworker, understanding these key factors ensures you’ll choose a tool that delivers reliable performance, clean cuts, and excellent value over time.

WEN Tenon Cutter Set with Carrying Case

The WEN DB051T 5-Piece Tenon Cutter Set is a versatile option designed for both beginners and professionals. This kit includes five cutters in different sizes, allowing you to handle a wide variety of projects from small metal rods to larger dowel joints.

Made from high-speed steel, the blades stay sharp longer, reducing downtime and ensuring clean cuts on softer and medium-grade metals. The set also comes in a durable carrying case, making it easy to store and transport.

Thanks to WEN’s reputation for producing reliable and affordable tools, this cutter set is a great entry point for anyone looking to expand their workshop capabilities without overspending.

Key Features

- 5-piece cutter set with multiple sizes.

- High-speed steel blades.

- Includes protective carrying case.

- Works with handheld drills and drill presses.

Pros

- Great value for beginners.

- Wide size range included.

- Portable and organized storage.

Cons

- Not ideal for heavy-duty industrial use.

- May require frequent sharpening on hardened metals.

Lasnten 5-Piece Tenon Cutter Set with Case

The Lasnten Tenon Cutter Set is built for precision and durability. Featuring five different sizes, this set is perfect for wood and light-to-medium metal projects, offering clean, consistent results.

Each cutter is crafted from high-carbon steel, which enhances durability and cutting efficiency. The kit is packed in a sturdy carrying case for protection and organization. While not as heavy-duty as industrial-grade cutters, the Lasnten set strikes an excellent balance between performance and affordability.

For DIY enthusiasts and small shop owners, it’s a reliable choice that provides both functionality and convenience.

Key Features

- 5 different cutter sizes.

- High-carbon steel construction.

- Compact carrying case included.

- Compatible with most drills.

Pros

- Affordable yet reliable.

- Good for multi-material use.

- Easy to carry and store.

Cons

- Limited to thicker metals.

- Better suited for occasional rather than daily use.

MAX CRAFT Tenon & Dowel Cutter Drill Attachment

The MAX CRAFT Tenon & Dowel Cutter Drill is designed for metalworkers who need versatility in shaping both tenons and dowels. Built with high-speed steel cutting edges and a robust body, it handles mild steel and aluminum with ease.

Unlike basic sets, this cutter attachment is specifically optimized for drill use, making it convenient for quick setups and portable projects. Its precision design reduces chatter, ensuring smoother cuts and minimizing the need for post-processing.

For users seeking an affordable yet durable tool for light-to-medium metal cutting, the MAX CRAFT cutter provides solid results.

Key Features

- Dual-function (tenon and dowel cutting).

- High-speed steel blades.

- Drill-optimized design.

- Works with multiple metal types.

Pros

- Multipurpose use.

- Strong cutting performance.

- Affordable and lightweight.

Cons

- Not ideal for large-diameter cuts.

- Better for DIY than heavy professional use.

HARFINGTON Tenon Cutter Drill Set

The HARFINGTON Tenon Cutter Drill Set stands out for its high-quality craftsmanship and focus on precision. Designed with hardened steel blades, this set can withstand repeated use on metals without quickly dulling.

It’s especially useful for furniture makers and metal fabricators who require consistent, professional-grade results. The kit includes multiple cutters and comes packaged in a durable box, ensuring protection and easy storage.

HARFINGTON is a trusted name in woodworking and metalworking tools, making this set a smart choice for anyone looking to upgrade their workshop.

Key Features

- Hardened steel blades.

- Multiple cutter sizes included.

- Long-lasting durability.

- Compact, durable case.

Pros

- Built for heavy-duty tasks.

- High cutting precision.

- Excellent for professional workshops.

Cons

- Higher price point than basic sets.

- It may be overkill for hobbyists.

Aepiraza Tenon Cutter Drill Set

The Aepiraza Tenon Cutter Drill Set is designed for versatility and portability. With multiple diameter options, it’s suitable for both woodworking and light metal projects. Made with carbon steel cutters, this set strikes a balance between durability and affordability.

It’s compact and lightweight, making it perfect for DIY enthusiasts, small workshops, and mobile professionals who need reliable tools on the go. While it may not match the longevity of premium hardened steel sets, Aepiraza delivers solid performance for its price point.

Key Features

- Carbon steel cutter set.

- Multiple size options.

- Compact carrying case included.

- Lightweight and portable.

Pros

- Budget-friendly option.

- Great for occasional metal cutting.

- Easy to transport.

Cons

- Less durable for daily heavy use.

- Requires frequent sharpening.

Frequently Asked Questions (FAQ)

Can I use a tenon cutter for stainless steel?

Yes, you can use a tenon cutter on stainless steel, but you’ll need the right type of cutter. Stainless steel is much harder than aluminum or mild steel, which means standard carbon steel cutters will dull quickly and may even overheat. For stainless steel, the best choices are:

- High-speed steel (HSS) cutters: These are affordable and perform well on stainless steel if used correctly. They resist heat better than carbon steel.

- Carbide-tipped cutters: These are more expensive but offer superior durability and can withstand prolonged cutting without losing sharpness.

When cutting stainless steel with a tenon cutter, it’s important to:

- Use cutting lubricant to reduce friction and heat buildup.

- Keep RPMs lower than when cutting wood, usually around 300–600 RPM, depending on your drill and cutter size.

- Take breaks between cuts to prevent overheating.

In short, while stainless steel is a challenge, the right cutter and proper technique make it possible. If you regularly work with stainless steel, investing in a carbide-tipped tenon cutter is highly recommended for longevity and clean results.

Do I need a special drill for tenon cutters?

Not necessarily. Most tenon cutters are designed to fit standard handheld drills and drill presses, so you won’t need specialized equipment. However, a few things will make your experience much better:

- Variable-speed drills: These are essential because different metals require different cutting speeds. Too much speed can overheat the cutter, while too little may cause chatter.

- High-torque drills: Metal is harder to cut than wood, so a drill with strong torque is necessary to maintain smooth cutting pressure.

- Drill presses: While handheld drills work fine, a drill press provides better stability and precision. It holds the workpiece steady, ensuring consistent cuts.

If you’re a DIYer working on occasional projects, a corded handheld drill with variable speed will do the job. But if you want professional-grade accuracy, especially on tougher metals, a drill press or magnetic drill press is worth the investment.

Pro Tip: Always check the manufacturer’s compatibility recommendations. Some tenon cutters list ideal RPM ranges or torque requirements, which can help you match them with the right drill.

How do I keep my tenon cutter sharp?

A sharp tenon cutter is critical for smooth, clean cuts and long tool life. Here’s how to maintain sharpness:

- Use proper cutting speeds: Running the cutter too fast on metal causes heat buildup, which quickly dulls blades. Always follow the recommended RPMs.

- Apply cutting lubricants: Oils like cutting fluid or even WD-40 reduce friction and extend the life of your cutter by preventing overheating.

- Sharpen regularly: Use a fine file, diamond stone, or bench grinder to restore sharp edges. A light touch is important to avoid removing too much material.

- Inspect after each use: Look for chips, nicks, or uneven wear. If the blade is damaged, it may need replacement.

- Store cutters properly: Keep them in a protective case or sleeve. Exposure to moisture can cause rust, which dulls the cutting edge.

For frequent metalworkers, investing in a sharpening jig or professional sharpening service can keep your cutters in peak condition without the risk of over-grinding.

Are tenon cutters only for professionals?

No, tenon cutters are not limited to professionals—they’re designed for a wide range of users. Here’s how they break down:

- Hobbyists & DIY users: Many budget-friendly sets, like those from WEN or Aepiraza, are ideal for occasional use. They’re easy to operate and often come in portable cases. DIYers use them for furniture repairs, custom builds, or small metal projects.

- Intermediate users: Makers, small-shop owners, and hobbyist metalworkers benefit from mid-range sets with more durable materials (like high-carbon steel). These offer a balance between affordability and reliability.

- Professionals: Heavy-duty sets, such as HARFINGTON or carbide-tipped models, are built to withstand daily use on tough materials. They provide the precision and consistency needed for production work.

So, whether you’re a weekend tinkerer or a full-time fabricator, there’s a tenon cutter drill suited to your needs. The main difference comes down to budget, material type, and frequency of use.

What’s the difference between a tenon cutter and a dowel cutter?

While the two tools are sometimes confused, they serve different purposes:

Tenon Cutter

- Creates tenons, which are projecting parts of a piece designed to fit into a corresponding mortise (slot).

- Commonly used in joinery, especially for metal or wood furniture making.

- Example: Making the end of a metal rod fit snugly into a joint.

Dowel Cutter

- Produces round dowels, which are cylindrical rods often used as pins, pegs, or fasteners.

- More commonly seen in woodworking, though some metalworkers use them for specific applications.

- Example: Cutting uniform dowels to pin joints together.

Interestingly, some tools—like the MAX CRAFT Tenon & Dowel Cutter—are designed to handle both tasks. This versatility is great for users who want a 2-in-1 tool, but for specialized work, a dedicated cutter for each function often provides cleaner results.

Conclusion

Choosing the best tenon cutter drill for metal depends on your needs, budget, and project scale. For beginners, the WEN DB051T and Lasnten sets provide great value.

If you’re looking for more precision and durability, the HARFINGTON set is a professional-grade investment. For versatility, the MAX CRAFT cutter shines with its dual-purpose design, while the Aepiraza set offers a lightweight, budget-friendly option.

By considering cutter material, size range, compatibility, and durability, you’ll be able to select a tool that ensures clean, accurate, and long-lasting results in your metalworking projects.